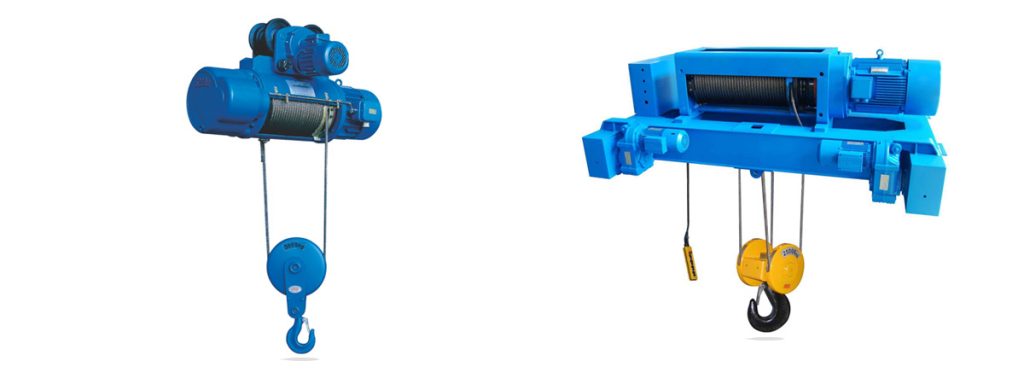

The manufacturing industry is constantly evolving, driven by the need for higher productivity, efficiency, and safety in operations. A key aspect of this transformation is the growing use of advanced material handling systems such as electric hoists and crane kits. These devices have become essential tools for industries that require precise lifting and transportation of heavy loads, including construction, automotive, warehousing, and industrial manufacturing. As technological innovation advances, electric hoists and crane kits are being designed with enhanced capabilities that not only boost productivity but also ensure greater safety and ease of use. One of the most significant trends in modern electric hoists and crane kits is the shift toward automation and intelligent control systems. Today’s electric hoists are equipped with smart features like remote control operation, load-sensing technology, and programmable settings that allow operators to handle loads with precision. For instance, load-sensing technology helps prevent overloads by detecting the weight of the material and adjusting the operation accordingly. This minimizes the risk of accidents and equipment damage, contributing to a safer work environment. Furthermore, remote operation allows for more efficient handling, enabling workers to control hoists from a safe distance, especially in hazardous environments. This move toward automated and remote-controlled systems is raising operational standards across industries.

In addition to automation, the latest polipasto eléctrico and crane kits are designed to improve energy efficiency. Manufacturers are incorporating advanced motors with variable frequency drives VFDs, which regulate the speed and torque of the motor, thus conserving energy and reducing wear on the equipment. This not only cuts down on operational costs but also extends the lifespan of the machinery. Additionally, many of these systems are designed to be lightweight and compact, allowing for easier installation in tight spaces while maintaining their strength and durability. The move toward more efficient designs is helping industries lower their carbon footprint while improving overall operational sustainability. Safety continues to be a primary focus in the development of electric hoists and crane kits. With industries handling increasingly larger loads, the risk of accidents due to equipment failure or misuse is ever-present. To mitigate this, manufacturers are integrating more robust safety features into their designs. This includes enhanced braking systems, emergency stop functions, and overload protection mechanisms. Moreover, modern electric hoists are built with redundant safety features that prevent free-falling loads in case of a mechanical failure. These innovations significantly raise safety standards, reducing workplace accidents and downtime caused by equipment malfunction.

Finally, modular crane kits have become popular due to their flexibility and ease of customization. These kits allow industries to configure their cranes to specific needs, whether for lifting, transporting, or positioning materials. By choosing from a range of components like hoists, trolleys, and beams, companies can build tailor-made systems that fit their operational requirements without investing in entirely new equipment. This modular approach is cost-effective and allows for scalability as businesses grow. In conclusion, electric hoists and crane kits are at the forefront of raising manufacturing standards through technological innovation. With advancements in automation, energy efficiency, safety, and modular designs, these tools are essential for industries looking to enhance productivity, reduce costs, and improve workplace safety. As manufacturers continue to push the envelope, we can expect even more sophisticated and user-friendly systems in the near future.